Behind the Scenes: How a Lingerie Brand Designs a Custom Lace

Today's guest post is from Larissa King. Larissa has been designing (and writing) for Hanky Panky since 2003. She lives in upper Manhattan, where she creates handmade dancewear under the name Entrechat Dance. Her interests include ballet, history, art, design, textiles, watching 1970s Doctor Who, and eating plants.

Hanky Panky's Annabelle Lace

A recent thread on the Lingerie Addict’s facebook group led to an article by the independent couture lingerie designer Karolina Laskowska, wherein she listed the myriad challenges involved in commissioning and creating custom laces for one’s brand.

While the challenges she wrote about are absolutely real, my experience designing for a slightly larger brand at a middle-to-better price point differs from hers. So, I thought I’d share some of my experience working with lace suppliers to create custom laces for the brand I design for.

Why Use Exclusive Laces?

Market differentiation! In this crowded industry, having unique product is crucial. As clothing designs are not copyrightable in the United States (or even patentable if the design has any functional elements), many better brands invest their resources into creating prints, embroideries and lace designs, which ARE granted copyright protection. This helps protect innovators from imitators.

Having laces designed just for one’s brand allows more control over the final look of the garments and also over qualities that can affect the fit and feel of the finished product. When designing lingerie, it’s absolutely critical that the materials used are as soft as possible and have the correct amount of stretch and recovery, as that affects the fit of the final garments.

If you go to a department store or boutique, you can often tell what brand an item is without looking at the label, just by looking at the laces used. The brand I design for has several suites of laces and trims which are recognizable as our patterns and not available from our competitors.

Likewise, other brands at the better price point, such as Natori and Wacoal have their own unique laces. A basic panty silhouette will look very different in the different laces, and using exclusive lace designs gives each brand their own look and fit.

Ensuring Exclusivity

There are two ways to guarantee exclusivity for the laces used by your brand. The first and easiest is confining a design. This means after you decide to purchase a design from the lace house’s existing line for your collection, your brand negotiates a deal with the lace supplier ensuring that they will not sell the same pattern to your competitors.

Depending on the markets you sell to (and how much fabric you’re willing and able to commit to purchasing), you can negotiate the time period, region, and market segments that the confinement will apply to (e.g. 2 years, North America, lingerie). The lace house has to recoup their manufacturing and development costs with only one customer, so the order quantities involved are significant.

The other, more involved, way to ensure exclusivity is to work with your lace house to create a custom design for your specific requirements and brand aesthetic. This is the process we will explore in this article.

What kinds of lace can you have designed for your brand?

In my 14+ years designing lingerie, my experience is primarily having warp-knit machine laces custom designed. These include traditional raschel laces and more high-tech Textronic® and Jacquardtronic® laces.

As soft and comfy stretch laces are what the brand I design for sells the most, it wouldn’t make sense for us to custom design rigid leavers laces, which are undoubtedly beautiful, but are more expensive, slower to produce, and can only be used in limited ways.

One of the reasons the minimum quantities for custom stretch lace trims is so high is that multiple bands are knitted across the machine at once, and then separated by a scallop cutter after dyeing and finishing.

Traditional raschel knit laces do require relatively large amounts be purchased for a custom design (in the tens of thousands of yards), but if your brand plans to use these lace patterns across multiple seasons and in different ways on multiple styles, it’s an expense that can be spread out over a longer period of time. It’s definitely a commitment, and something one doesn’t jump into without a strong belief in the program, but it’s not as daunting as some might believe - particularly if you plan your designs to maximize your materials.

For smaller, more limited programs, one can work with the lace house’s designers on laces made on Textronic® and Jacquardtronic® lace machines. These types of laces are lovely, contain a lot of detail and have a delicate, lightweight look. They also have relatively smaller minimums and are easier to set up for a small “test” run before committing to tens of thousands of yards. These machines have a lot of flexibility and allow some for some interesting and unique uses, such as engineered lace panels designed for specific finished garments.

OK! I want to commission a lace! How does that work?

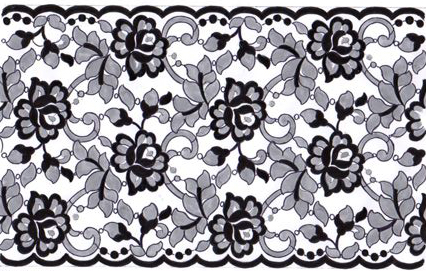

The lace mill submits a sketch for approval. (All rights reserved.)

It helps to have a good relationship with your lace supplier! The brand I work for has been working with many of the same lace houses for years (and are very steady customers), so when we approach them with an idea, they are usually receptive.

For example, recently we wanted to create a band using the floral motif of one of our allover laces and the width, yarns and lace type of our one of our more popular lace bands. We approached the lace house with the idea and their lace designer created a sketch for our approval.

The sketch is your first chance to make changes, like request that the motifs be bigger or smaller or change the size of the scallops, face the flowers a different way, etc. In the case of this particular lace design, we loved the sketch as-is.

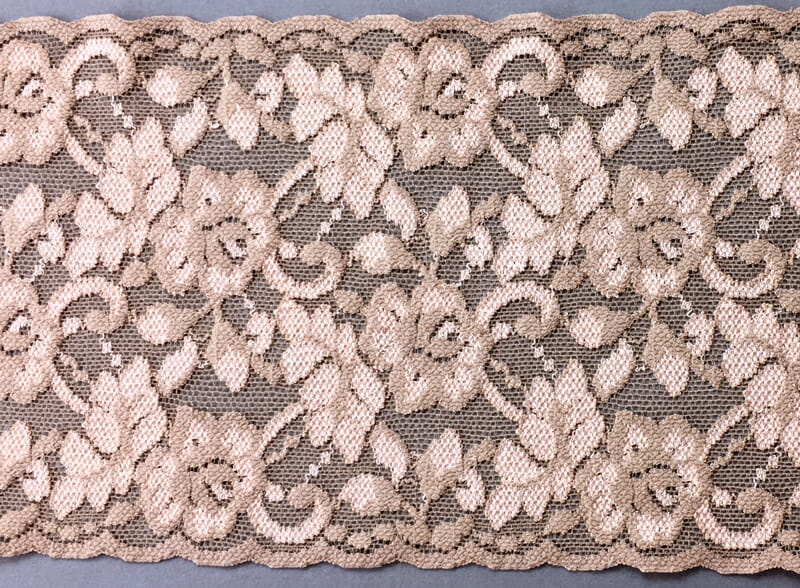

So, the next step was a knit-down. The mill programmed and set up a sample machine and created a small run of the lace design for approval. Here is the point where we could ask them to change the weight of spandex or how tightly or loosely the lace was knitted (which all affect fit).

Tada! The sketch becomes lace!

Once the design is all worked out and approved, the mill proceeds with production: knitting the greige goods (unfinished fabric) into batches of lace from machines called webs, lab dipping swatches of our chosen colors for approval, followed by dyeing and finishing the final product.

This is just one recent example. One can commission lace designs from all kinds of source materials and inspiration, from natural motifs, to antique embroideries, to trompe l’oeil effects, and even cartoon characters! The important thing is to keep in mind that you’ll be working with (and selling) this lace for a while, so you want to ensure that it’s a commercially viable design with a broad appeal.

I hope this demystifies some of the lace design and production process. If there’s anything you’d like more information on, feel free to ask in the comments!